How to Choose the Best Crane Manufacturer in India

In today’s growing manufacturing industry, choosing the right crane is necessary for the safety, performance, and productivity of your industrial needs. Whether you’re in manufacturing, warehousing, steel, cement, or any heavy-duty industrial sector, choosing the best crane manufacturer in India ensures long-lasting performance and smooth operations. With many manufacturers across the country, finding a trustworthy and well-established partner can be necessary. That’s why Bright Crane Equipment, one of India’s leading crane manufacturers Here to guide you through the primary factors to consider: The first thing to find is a manufacturer’s track record in the industry. Well-established manufacturer with a deep understanding of industry challenges and solutions. Bright Crane Equipment, with its years of experience and successful installations across India and globally, has become a trusted name for overhead cranes customized to specific industry requirements. Always choose a crane manufacturer that meets ISO certifications and industry safety standards. A certified and submissive crane means peace of mind for your operations and your workforce. Bright Crane Equipment prioritizes safety, engineering accuracy, and smooth operation in every crane system. Each crane is strictly tested and made with high-quality components for long-lasting performance. Modern industries ask for automation, smooth operation, and less downtime. Look for a manufacturer that offers cranes equipped with advanced technologies such as VFD (Variable Frequency Drive) control panels, remote operation systems, anti-sway mechanisms, and load monitoring tools. Bright Crane Equipment stays ahead of the loop by integrating the latest in crane technology, ensuring smooth, power-saving, and high-performance operations. After-sales client support is the main factor for long-term investment, This makes after-sales service a primary part of the decision-making process. Bright Crane Equipment offers Annual Maintenance Contracts (AMC), spare part availability, and 24/7 support to ensure your operations never face unnecessary downtime of operation. One of the best ways to choose a manufacturer’s loyalty is through customer testimonials and past client experience. Bright Crane Equipment has successfully delivered crane systems for a large range of clients across India—from SMEs to large-unit industries, earning a reputation for quality, service, and on-time delivery. Choosing the best crane manufacturer in India comes down to expertise, customization, alignment, technology, and service. By choosing Bright Crane Equipment as your partner, you’re investing in quality, performance, and a long-term solution customized to your specific requirements. Are you looking for the right crane for your industrial needs? Get in touch with Bright Crane Equipment today for a free consultation and quote. Visit brightcraneequipment.com to learn more.

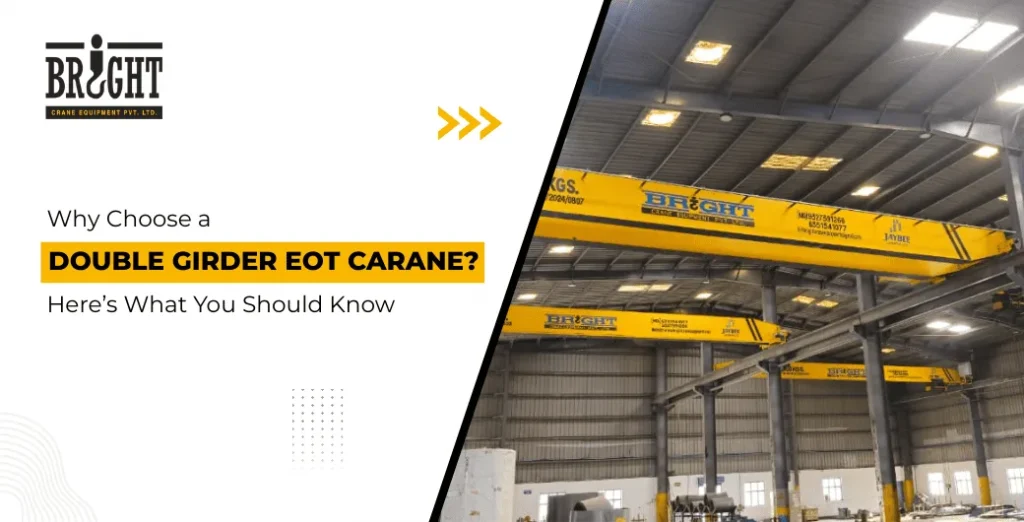

Why Should You Choose a Double Girder EOT Crane? Here’s What You Need to Know

In industrial operations where material handling plays a primary role, selecting the right type of crane can affect productivity, and safety. Among the many crane types available, the Double Girder EOT (Electric Overhead Travel) Crane stands out for its heavy-duty capabilities and strong design. Whether you’re working in manufacturing, fabrication, power plants, or logistics, This Double girder EOT crane offers high-performance for lifting and transporting heavy loads with accuracy. What is a Double Girder EOT Crane? A Double Girder EOT crane features two main girders that support the hoist trolley, which transfers between the girders. This design allows for better load distribution, improving lifting capacity, and a higher hook height compared to single girder models. These cranes are generally used in environments where lifting loads of more tons is routine and performance and quality are mandatory. Key Benefits of Choosing a Double Girder EOT Crane: The Double girder EOT structure allows the crane to lift heavy loads, and give high-performance making it perfect choice for industries requirements that deal with large, bulk materials. It offers the smoothness and balance needed for safe and productive industrial operations, even under harsh environmental conditions. Double Girder EOT Cranes offer a higher height, which means the crane hook can reach closer to the ceiling. This allows for better use of vertical space—an important factor in plants and warehouses with height constraints. The large span also enables the crane to cover a larger area smoothly. When sourced from a trusted Double Girder EOT Crane Manufacturer, these cranes are made using high-quality materials and accurate engineering. They are manufactured to withstand harsh working environmental conditions, requiring low maintenance while delivering consistent performance for a longtime. A well-known Double Girder EOT Crane Supplier can customize according to specific operational requirements. This includes special hoists, anti-collision systems, radio remote control, inverter drives, and more, ensuring that your crane fits perfectly into your workflow. Ahmedabad has emerged as a main industrial center in India, known for its strong and growing infrastructure and manufacturing center. Many well-known and trustworthy Double Girder EOT Crane Manufacturers in Ahmedabad offer advanced technology, affordable pricing, and committed after-sales customer service. Working with a Double Girder EOT Crane Supplier in Ahmedabad also means after installation and easier access to spare parts and maintenance services locally after installation. Final Words A Double Girder EOT Crane is a long-term investment in your business’s productivity and safety. With smooth load handling, improved service life, and customised design options, it remains the best choice for heavy-duty applications across industries. Partner with a trusted Double Girder EOT Crane Manufacturer or Supplier in Ahmedabad to get the best value, performance, and quality for your industrial operations.

How Jib Crane Manufacturers Are Improving Workplace Safety

Workplace safety is a major priority in the modern work environment and many top companies are also investing in technologies to mitigate risk and ensure the well-being of their employees. Among all the innovations that have contributed to workplace safety, jib crane is the one. Jib cranes are designed keeping in mind the efficiency and likelihood of the workplace accidents. New features and technologies provided by the best Jib crane manufacturers will benefit both businesses and workers. So, in this blog we understand how jib crane manufacturers are improving workplace safety. The major way through which the advanced crane manufacturers are improving the workplace is with the invention of user-friendly jib cranes. Traditional cranes used to cause multiple accidents because they were complex, bulky, and difficult for workers to operate. On the other hand, modern jib cranes are equipped with advanced features which reduces the struggle. Features like easy-to-use controls, adjustable heights, etc. allows the workers to lift and move materials with minimal physical effort. The improvement in load control system is another significant advancement when it comes to cranes. There are multiple work environments where handling heavy materials can have significant safety risks if the task is not done properly. So, to address this, jib crane manufacturers are using advanced load control technologies that improve the stability of the crane during lifts. This reduces the risk of accidents and allows the operators to manage the lifting process from a safe distance. Another major innovation of the best jib crane manufacturer is its anti-collision system. There are multiple industries where different machines work at the same time and in the same environment, and this increases the risk of accidents. To minimize this situation, there are many modern jib cranes that are equipped with anti-collision sensors and technologies. There are cranes that stop automatically when they sense any issue to avoid accidents. PAN India along with Jib crane manufacturers in Ahmedabad pays close attention to industry safety standards and regulations. To ensure that the equipment meets the highest safety criteria, many jib crane manufacturers design it in line with international standards. By addressing the safety standards, jib crane manufacturers ensure that they are following all the safety guidelines and contribute greatly to a safer workplace. A crucial role is played by the jib crane manufacturer in improving the workplace safety by adapting new changes and technologies. Remember to invest in the right jib crane manufacturer like Bright Crane Equipment Pvt. Ltd. and foster a culture of safety for your employees.

The Benefits of Working with Single Girder EOT Crane Manufacturers

The EOT in EOT crane manufacturer stands for Electric Overhead Travelling and it is being used in multiple businesses for lifting a range of materials. When it comes to cranes, businesses are often confused whether to buy a crane locally or to go for an international manufacturer. As per EOT crane manufacturer in India, there is no doubt that global manufacturers offer advanced features and competitive prices, however, there are significant advantages when you go with Single Girder EOT crane manufacturers. So, let’s explore the truth and understand the benefit of working with Single Girder EOT crane manufacturers. When you go for a Single Girder EOT crane manufacturer, you enjoy personalized and responsive customer services. Unlike larger, international companies, crane manufacturers offer dedicated teams that understand all your specific needs and daily challenges. In addition, local manufacturers are typically more proactive in addressing issues quickly. You can also expect a much quicker response time from a local supplier as they value your business more. Single Girder EOT crane manufacturers provide you with faster turnaround time. Local suppliers work closely with you which allows them to provide quicker deliveries of both spare parts and products. Unlike international suppliers, if in any case you require custom modifications or any specific changes, Single Girder EOT manufacturers will be able to help you quickly. This faster turnaround is important in industries that run on tight production schedules and where equipment delay or breakdown can result in costly downtime. Contacting a Single Girder EOT crane manufacturer can help you reduce the transportation costs. If you contact an international supplier, it will cost you high shipping fees. However, a supplier located nearby will deliver the product within no time, without any high shipping charges. Opting for Single Girder EOT crane manufacturers have a positive environmental impact as it reduces the need for long-distance shipping which minimizes the carbon footprint which is associated with transporting heavy items across the borders. As smart business owners are prioritizing sustainability, buying an EOT crane locally is simply the best option. Choosing to go with a Single Girder EOT crane manufacturer provides a range of benefits. Apart from the points mentioned above, it also provides support for the local economy and following the local regulation and standards. This is a very smart decision and if you are looking for a Single Girder EOT crane manufacturer in Ahmedabad, contact Bright Crane Equipment. Remember, whether you are looking to reduce downtime, support your community, or focus on sustainability, going for a Single Girder EOT crane manufacturer is the right option.

Top 5 Crane Manufacturing Companies in Ahmedabad

When it comes to cranes, it is important to make the purchase from a top-tier company to ensure reliability, quality, and safe equipment. Looking for a top-tier crane manufacturer is also important as it provides various other services like training, maintenance support, after-sale services, and other technical assistance. Especially in a city like Ahmedabad, where almost every manufacturer is a crane manufacturer, it is important to find the right one. Top 5 Crane Manufacturing Companies in Ahmedabad are: Now, Lets Understand the Role of a known Cranes Manufacturing for Companies Safety is a major concern in any manufacturing environment or industry, and here, a crane plays a significant role in enhancing the safety of the workplace. As a crane is used for lifting heavy loads and materials, a risk is always associated with it. Therefore, if you opt for a crane from a known manufacturer, it reduces the chances of workers suffering from injuries and any type of severe accident. As we all know that the major role of a crane is lifting and moving the heavy loads. Many big manufacturing companies even require the handling of heavy and bulky components which range from wood to steel. In this scenario, manually lifting or moving the heavy items can be time-consuming and very dangerous. In addition, in production houses, where time is money, going advanced by reducing the manual labour is important to boost productivity and this is a reason you should go for renowned crane manufacturing companies. Cranes allow manufacturers to utilize vertical space. For instance, overhead cranes can move components and materials upwards, and store them high above the ground. So, this ability to stack materials and goods vertically frees up floor space for additional manufacturing processes which ensures that operations remain smooth and going even in tight space. In addition, as per crane manufacturer company in Ahmedabad, cranes are also used to organize and retrieve materials which reduces the time spent in searching for products and ensuring that inventory management is working timely. Cranes are not just a manufacturing tool, it is a key player that drives efficiency, safety, and productivity. Cranes designed by top-tier companies ensure that all the work is carried out safely and smoothly without any wear and tear. Therefore, in today’s competitive world, incorporating cranes with a well-established crane manufacturing company is important for maintaining a high level of productivity while safeguarding the well-being of the workers.

What is a Double Girder EOT Crane?

Double Girder EOT crane, where EOT stands for Electronic Overhead Travelling, are machines made up of two girder beams. These beams are supported by an end truck. This invention is the requirement of almost every manufacturing business, whether it is shipyarding, iron & steel products, automobile sector, metal industry, etc. This is a crane which is used by big manufacturing industries for heavy-duty applications. This mainly refers to tasks that need longer spans and higher capacities. You can lift heavy loads easily and with safety on a frequent basis. Understanding about a double girder EOT crane can be easy but choosing the right one for the business becomes a difficult part. As per a double girder EOT crane manufacturer, there are some right ways to select the right crane for the industry, and these are: Studying about the actual capacity you need to lift is very important while finalizing a double girder EOT crane. This will help you know about the crane and invest in the right one, while saving your time and money. Before finalizing a double girder EOT crane, it is important to know the span in detail. A span is the distance between the two rails. It is being calculated on the basis of the size of the area where it will be operated. Remember, the size should not be too small as it will make it difficult for the crane to reach all the places where lifting is needed. Here, the height of lift means the maximum height to which a double girder EOT crane can lift loads. So, it is important to select a double girder crane that lifts as per your height requirement. If the height of the lift goes too high, it might cost you extra. This is an important consideration while looking for a double girder EOT crane as advanced safety tools will help you prevent accidents and emergency situations. Some common safety features provided by double girder EOT crane manufacturers are safety locks, overload protection, and emergency stop button. Double girder EOT crane is a powerful machine and is working as a lifeline for multiple companies. Its effectiveness is famous in the market and if you are also looking for one, contact Bright Crane Equipment Pvt. Ltd. Invest in the right crane and enhance your operations.

Why Quality Matters in Crane Manufacturing?

Crane manufacturing in India is an industry where quality and safety matters the most. There is no doubt that cranes are complex machines that play an important role in a range of sectors like mining, shipping, construction, and industrial operations. However, a crane with poor quality can become very dangerous for both the working space and employees. Therefore, the quality of the crane becomes very important. Here are some reasons for the same: As per crane manufacturers, cranes are expensive assets for businesses and therefore investors expect it to perform reliably over many years. Moreover, cranes are subjected to extreme conditions, including harsh weather, continuous use, and heavy loads. Therefore, in crane manufacturing, quality becomes important to withstand the test of time and demand. As per crane manufacturers in India, the most critical factor in crane manufacturing is its safety. Cranes are machines that are responsible for lifting heavy loads and one failure in its design, material, or assembly can lead to major accidents and injuries. Therefore, it becomes important to prioritize its quality to minimize the risk. As per expert crane manufacturers, cranes must meet a range of regulations, which vary by industry, country, and project. These regulations involve strict criteria like load testing, weight capacity, and other safety features. Quality crane manufacturers ensure that their products meet or exceed these standards, which will not only prevent legal issues but it will also ensure that their cranes can be used in multiple settings without any issue or problem. As per crane manufacturers, while high-quality cranes may come with a higher initial price tag, they are more cost-effective in the long run. If the quality and material of the crane is poor, it will need frequent repairs and will suffer from high maintenance costs. Therefore, by investing in the material and quality of the crane, investors can save expensive operational disruption. Not only this, it will also offer better fuel efficiency and will lead to significant savings. In the crane manufacturing industry, trust and reputation is everything. Companies with high quality crane materials build trust and lead to repeat business. Therefore, the quality of the crane matters. If you are looking to invest in a crane manufacturing company in Ahmedabad, contact Bright Crane Equipment PVT. LTD., as they offer high-quality cranes with excellent functionality. Quality is more than just a word when it comes to crane manufacturing. As an investor, always remember to invest in the right crane as if the crane manufacturing is weak, your operations will be affected, which will at last affect your overall business.

Top Crane Manufacturing Companies in Gujarat

Cranes are the unsung hero of any manufacturing company as it works silently behind the scenes and easily replaces the need for human strength to lift heavy goods. A crane is used in both big and small manufacturing units to carry and move tools and equipment from one place to another. The crane manufacturing companies in India, especially in Gujarat, designs a range of cranes to help the manufacturing companies in increasing their productivity, ensure safe working environment, and save operational time. Before going further, let’s discuss some major companies of Gujarat that manufacture cranes. Krishna Crane Engineers This crane manufacturing company was established in the year 2005 and its facility is located in Ahmedabad, Gujarat. This company works on cranes like single girder cranes, EOT cranes, JIB cranes, double girder cranes, etc. Bright Crane Equipment Private Limited Bright crane is a leading crane manufacturing company in Ahmedabad, Gujarat. Till date, it has completed 950+ projects and has served 100+ industries of various sectors. This company designs advanced and world-class cranes like double & single girder EOT crane, JIB crane, chain hoist, wire rope hoist, and goliath crane. Ganesh Engineering Co Established in the year 2004, Ganesh Engineering Co is a crane manufacturing company that designs cranes like JIB crane, Wire Rope Hoists, Goods Crane, EOT crane, etc. This company is located in Ahmedabad, Gujarat. Meeka Machinery Private Limited Situated in Ahmedabad, Meeka Machinery Private Limited is a crane manufacturing company in different industries, whether government or private. The company came into existence three decades ago and designs cranes like overhead crane, hoist crane, JIB crane, etc. Inovic CRM India Private Limited Established in the year 2011, this company is situated in Ahmedabad, Gujarat. This company manufactures cranes like chain hoist, EOT crane, JIB crane, double girder crane, etc. Crane Type as per Working Now, as we know the top five crane manufacturing and supplying companies in Gujarat, let’s discuss different types of crane as per its working. Cranes are used in a range of industries like construction, maritime, shipping, manufacturing, utilities sector, energy, infrastructure, transportation, extraction, mining, forestry, agriculture, aviation, military, aerospace, and even entertainment. Benefits of Cranes Crane offers a range of benefits in manufacturing units, and these benefits are: Load Capacity: Different cranes have different load capacity. If you are looking for a crane to lift heavy weight, choose the crane wisely as the wrong crane can cause a serious accident. Versatile: Unlike traditional cranes, modern cranes are versatile in nature as it meets the handling demands of various materials. Safety: The risk of injury can be reduced if the operator is trained and follows all the safety instructions and protocols. Moreover, modern cranes come with various safety features which makes the working environment safe to work. Space Optimization: Unlike traditional cranes, modern cranes are designed to fit in any space. Like gantry cranes and overhead cranes are designed to fit in vertical space. This feature helps the industries in organizing the workspace and maximizing the storage area. While using a crane, the company should take some important safety measures. Safety measures are important to avoid workplace injuries and accidents. Some major things that you should keep in mind and take in practice are giving proper training to the operators, go for pre-operational checks, check for limited load capacity and load stability, and have clear communication with the team. The above mentioned safety features will not only make the crane operations smoother, but it will also help you save time and cost by reducing time wastage and extra costing. In conclusion, it is clear that cranes have changed the way manufacturing units worked earlier. Unlike traditional processes, modern cranes have made the lifting task easier and it has made the operations smoother. Along with this, the list of top crane manufacturing companies mentioned-above will help you in finalizing a company for your investment. Also, in the future, it is clear that advanced technology in cranes will change with time and it will enhance the needs of the industries. So, choose the right crane for your business and enhance your productivity in the coming years.

What Kind of Problems do Crane Manufacturers Face in India

There are multiple industries that go through multiple challenges, and the material handling equipment industry is not behind. There is no doubt that in the past few decades, the crane manufacturing industry in India has witnessed a significant amount of growth. However, this industry has faced multiple challenges, from handling the piece of equipment to controlling and protecting the materials. The crane manufacturers design cranes for multiple applications, fulfilling the demands and requirements for a range of industries, and this increases the demands of cranes. The crane manufacturers in India are enjoying some benefits, however, they are also facing some challenges and in this blog, we will explore in detail some issues and problems that these manufacturing companies face in India. Skilled Labor Shortage Despite being a country with the largest population, India faces a shortage of skilled labor. This shortage affects the crane manufacturing industries in India. Designing and planning a crane requires excellent knowledge in engineering, electrical systems, and mechanics. There are many trained workers available in the market, but they are mostly trained with the traditional methods and lack exposure to modern technologies and practices. This becomes a major challenge for manufacturers. So, to overcome this, the crane manufacturers need to invest rightly in the training and development program of the laborers to bridge the skill gap. This will be both time and money consuming, but will work excellently in the long-run. Technology Integration The technology is growing at a rapid pace and this is both an opportunity and a challenge for crane manufacturers. Now-a-days, industries are working with high-tech and modern technologies, and therefore, they look for crane solutions that are equipped with advanced technology. So, to stay in the market and in competition, it has become important for crane manufacturers to opt for new technologies like AI and other automations. EOT crane manufacturers need to integrate these technologies into the existing technology. There is no doubt that this might become complex, challenging, and costly, but this is an important investment. Economic Volatility The crane manufacturing industry can be impacted directly by the Indian economy as it is subject to fluctuation. Particularly in infrastructure and construction projects, economic downturns can lead to a reduction of the crane’s demand. This is a kind of challenge in India for the manufacturers and to overcome this, they need to prepare themselves for economic shifts, which might involve exploring new markets and product offerings to mitigate risks. This step is important if you want to survive and stand out in the market as EOT crane manufacturer, India. Competition from Global Players Every coin has two sides, and this quote goes well with globalization. On one side, where globalization has opened multiple doors of opportunities, it has made it quite difficult for some companies to stay in the sales. Globalization has affected the business of Indian crane manufacturers as it has stiffed the competition and now the international crane manufacturers are the king of the market. This happens because already established international crane manufacturers own large production, advanced technologies, a huge team of experts, and more significant financial resources. Therefore, Indian manufacturers must focus on unique selling propositions, high-quality products, and strategic partnership. One crane manufacturer that matches international level companies, both in management and technology is Bright Crane Equipment PVT. LTD. Quality Control Issues For crane manufacturers, maintaining high-quality and a set standard is important. This is important because chances of accidents increase while using a crane and for big industries, where the crane is being used on a daily basis, quality control issues become a big thing. There are various reasons through which quality control issues can arise. So, to overcome this, it is important for the manufacturers to prioritize training their workforce in quality standards to ensure customer satisfaction and minimize defects. In India, crane manufacturers are on a crossroad and are facing multiple challenges. All these companies need to do is address the issues mentioned above to overcome all these challenges. This will help them in surviving in the Indian crane manufacturer market. So, get ready to contribute to the Indian economy by embracing innovation and strategic planning. Because to become the leader in this field, manufacturers need to prioritize quality and adaptability.

What are the Different Types of Overhead Cranes available in the Market?

From shipping to manufacturing, overhead cranes play a crucial role in a range of sectors and businesses. This is a versatile machine that helps in lifting and moving heavy machines and materials safely and efficiently along with ensuring the productivity of the workplace. However, with multiple ranges of options available in the market, it becomes crucial to select the right type of overhead cranes for the right use. This is not rocket science, as with some research and right information, you will be able to differentiate between multiple cranes. Let’s explore a few overhead cranes available in the market, with their unique applications. EOT Bright Crane The EOT in EOT crane stands for electric overhead traveling. This is an overhead crane used by a range of industries for shifting and lifting heavy loads and weights. These are advanced cranes that use electricity to move and are operated by IR remote pendant, radio, control pendant, or an operator cabin. Not only heavy, but this crane is also used for lifting light weights. There are mainly two types of EOT cranes, that is single girder EOT cranes and double girder EOT cranes. Single-girder EOT cranes work on a single girder with a trolley and hoist that runs along. The main feature of this is that it is most suitable in lifting light objects and works in places that have compact constructions. On the other hand, double girder EOT cranes have platforms on both the sides. Its feature is that it can lift super heavy loads and it comes with alloy steel that provides excellent strength. Bridge Cranes Bridge cranes are cranes that move along two parallel tracks and are one of the most common types of overhead cranes. These cranes consist of a horizontal beam or bridge to move and work effectively. The bridge here is supported by end trucks that allow the movement to take place. These cranes are designed by crane manufacturers to be used in factories and large warehouses where heavy loads are needed to move across long distances. These cranes are versatile in nature and are used in multiple applications like manufacturing plants and assembly lines. Jib Cranes Jib cranes are interesting cranes as they are characterized by a horizontal arm which works with the support of a hoist. The jib cranes spin on a vertical post which allows it to have a wide range of motion. Crane manufacturers design this crane for a range of applications like manufacturing assembly, workstations, and small warehouses. These cranes are installed either on floor mounted pillars or walls on a permanent basis and are used for repetitive tasks. Use jib cranes for localized lifting, manufacturing, or assembly applications. Overhead Traveling Cranes Crane manufacturers design overhead cranes to travel along tracks that are mounted on the ceiling of the facility. These cranes are somewhat like bridge cranes but are often more versatile than them. These cranes are suitable for both big and small spaces. Overhead cranes are equipped with a range of lift up options and are mostly used in industrial and manufacturing environments like workshops, assembly operations, and small manufacturing plants. Hammerhead Cranes Hammerhead cranes are cranes that are mainly used in construction projects. These are huge cranes that rest on a fixed horizontal tower and resemble the shape of a hammerhead. These cranes can be used on heights very easily and that’s the reason why it is used for urban development. This crane also offers a feature known as racking, which allows the crane’s trolley to move backwards and forwards easily. These cranes are extremely heavy and are mainly used by constructors for the erection of tall structures and buildings. It is essential to choose the right overhead crane for your operations to maximize work efficiency and ensure safety. There are multiple types of cranes available in the market and each type offers unique advantages and suits specific applications. As a business owner, you need to understand about different cranes and its usage to meet your operations and make informed decisions. Always remember to consider some important factors while finalizing a crane like its loading capacity, lifting height, and other tasks that the crane can perform. By investing in the right overhead crane, you can improve your overall workflow and operations. Checkout Bright Crane if you are looking to invest in cranes, it is a well known crane manufacturer in Ahmedabad.